sa 333 gr 6 impact test|a333 gr6 minimum temp : convenience store Impact Requirements. For Grades 1, 3 and 6, the notched-bar impact properties of each set of three impact specimens, including specimens for the welded joint in welded pipe with wall . Bird Chinese Symbols - Chinese Symbols and Letters #1 (𝓒𝓸𝓹𝔂 𝓐𝓷𝓭 𝓟𝓪𝓼𝓽𝓮) ️

{plog:ftitle_list}

WEBSports Betting API. Lines move quickly, and inaccurate data could cost you and your customers big time. Time is money, stop using delayed data. Use the Optic Odds API to get the most accurate betting odds based on player news and injury reports. Optic Odds has hundreds of servers to process over 1 million odds per second, ensuring you always .

Shell piping specs for low temp using A333 Gr 6 requires impact testing at the specified lower design temp for temps ranging from 0degC to -50degC.This page introduced the impact test on ASTM A333 Gr.6 seamless pipes which are widely used in coolant piping systems of nuclear power plant, sour oil & gas pipeline, and offshore plant forms: impact temperature, specimens, testing .ASTM A333 Grade 6 pipe is common use material for low temperature services in above -45℃, with yield strength minimum at 240 Mpa, and tensile strength 415 Mpa.Impact Requirements. For Grades 1, 3 and 6, the notched-bar impact properties of each set of three impact specimens, including specimens for the welded joint in welded pipe with wall .

The ASTM A333 Grade 6 low alloy steel seamless pipes are intended for low temperature services with minimum design temperature -45°C [-50°F] requiring notch toughness: products & applications; chemical composition .

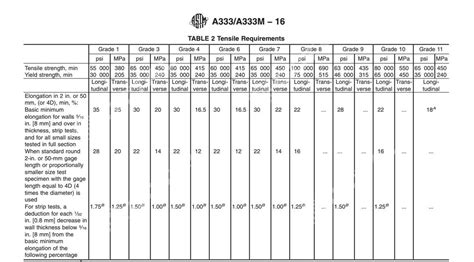

ASTM A333 covers nominal (average) wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures. Several grades of ferritic steel are included.Impact Test Value for ASTM A333 Grade 3, 6, 7, 9, 10 Pipe. Impact Test Temperature. Enpro offers ASTM A333 Grade 6 Pipe in Stock and New. Material available with seamless and welded in A333 Grade 1, 3, 6, 7, 8, 9, 10 and 11.

seam-less and welded carbon and alloy steel pipe intended for use a. low temperatures. Several grades of ferritic steel are included as listed in Table 1. Some product sizes may not be . So in reference to B31.3; SA-333-6 is exempted from impact testing if used as the base metal at -50F or higher; in conjunction with the fact that the material specification for SA-333-6 ask for impact testing to be performed.

astm a333 spec sheet

A333 Gr 6 WPS/PQR impact testing requirements Ray2020 (Mechanical) (OP) 3 Jul 20 06:00. . You could also use impact tested filler metals and be exempt for SA-333 Gr. 6. RE: A333 Gr 6 WPS/PQR impact testing requirements Dhurjati Sen (Materials) 8 Jul 20 12:13. I fully agree with weldstan. People are so fond of code jugglery that they simply .E 23 Test Methods for Notched Bar Impact Testing of Metallic Materials 3. Ordering Information . cation SA-333 in Section II of that Code. 3 For referenced ASTM standards, visit the ASTM website, . 6, 7, and 10 Grade 4C °F °C °F °C 1100 600 1150 620 . Impact Test For Pipe A333 Gr. 6 - posted in Industrial Professionals: Dear AllI need to know way of calculation temperature reduction when we use sub size specimen.My problem:I have tested an A333 Gr.6 (4" pipe-6.3 mm thickness). Labratoary used a sub size specimen (55*5*10). and they tested it in -48c. test temperature of A 333 Gr.6 is -45C and .

Using 333 Grade. 6 welded pipes are also viable due to them being highly weldable owing to the carbon content. However, most companies prefer seamless pipes as the performance improvements can be as high as 20% when using seamless pipes instead of welded pipes. . ASTM E 23 Test Methods for Notched Bar Impact Testing of Metallic Materials .

Find trusted and audited ASTM A333 Grade 6 Pipe suppliers in UAE, buy A333 Seamless Pipe, and LTCS SA 333 Gr 6 Material 10% to 40% cheaper price in Dubai.

Manufacturer of ASTM A333 Grade 6 Pipe in all dimensions, supplier of SA 333 Gr 6 Seamless, Welded, ERW pipes in Sch 40/ 60/ XXS in India, check Epoxy/ Galvanized A333 Gr 6 Material price in Mumbai. . ASTM A333 Gr 6 Impact Test. Size of Specimen, min: Min. Avg. Notched Bar Impact Value of Each Set of Three Specimens:Check Specification and Weight Chart of SA 333 Gr 6 Seamless Pipe. NACE Approved ASTM A333 Grade 6 Pipe Supplier in India, Buy ASTM A333 Gr 6 Material for Low Temperature Services . ASTM A333 gr 6 impact test. Size of Specimen, min J: 10 by 2.5: 10 by 3.33: 10 by 5: 10 by 7.5: 10 by 10: 5: 7: 9: 14: 18: Min. Avgerage Impact Value ft-lbf: 4: 5 .While the tensile properties of this alloy are moderate, according to this specification the LTCS ASTM A333 Gr 6 Pipe is put through the following tests - hydrostatic tests, and nondestructive electric tests in addition to tensile tests & impact tests.Apart from producing A333 Grade 6 Seamless Pipe, the welded pipe must not be welded by the use of any filler metal. A333 Gr 6 is typically used in applications where temperatures can drop as low as -50°F (-45°C), and its chemical composition is designed to provide high-impact toughness at these temperatures. This specification covers seamless and welded steel pipe for use in low-temperature service, and it requires impact testing at temperatures as low as .

ASTM A333 Gr.1, Gr.6, Gr.8 Seamless Low-Temperature Pipes ASTM A333 / A333M, ASME SA333 / SA333M Gr.6 is the standard applicable to seamless and welded steel pipe for low-temperature Service Quick Inquiry ASTM A333/A 333M covers nominal (average) wall seamless and welded carbon and alloy steel pipe intended for use at low temperatures.Chemical Composition of ASTM A333 Grade 6 Carbon and Alloy Steel Pipes Grade C, max Mn P, max S, max 6 0.30 0.29 - 1.06 0.025 0.025 Mechanical Properties of ASTM A333 Grade 6 Carbon and Alloy Steel Pipes Grade Tensile Point, min (MPa ) Yield Point, min (Mpa) Elongation, min (%) 6 415 240 30 / 16.5ASTM A333 (ASME S/A-333) Pipe grades permit low temperature service. This specification covers nominal (average) walled pipe almost exclusively in seamless. For applications of A333-6 pipe material below -45°C, there will be a requirement for impact testing. Benefits of ASTM A333 GR 6 CS Pipe. . SA 333 Gr 6 ERW Pipe: A333 Carbon Steel Schedule 40 Pipe: ASTM A333 Gr6 EFW Pipe: Asme A333 Cement Lined Pipe: SA333 Gr 6 Epoxy coated Pipe:

SA 106 has a higher impact resistance than SA 333. This means it can better resist being damaged by forces acting on it. . When it comes to choosing between SA 333 and SA 106 grade pipes, it all depends on the .Three and one half nickel material is manufactured from A/SA203 Grade D plate. Charpy V-Notch Impact Testing is required. Supplementary Requirements and an Appendix also address impact testing in this specification. . Refer to ASME B & PV Section II for non-identical A/SA requirements. Connect. Houston, TX- 281.443.7473; Schererville, IN .ASTM/ASME A/SA-333 Grades allow for cold temperature service to minus 150 degrees F. Material is always provided in the normalized condition at a minimum and Charpy Impact tested to a specific temperature range to assure . No, SA 106 Grade B would not have a higher impact value than SA-333 Grade B because of General note (c) referenced in UG-84. If you refer to Figure UG-84.1 in Part UG of ASME Section VIII, Div 1, the curve applicable for SA-106 Grade B is the lower one because of the lower specified yield strength of 35 Ksi, which would require a minimum CVN of .

cation SA-333 in Section Il of that Code. For referenced ASTM standards, visit the ASTM website, or . E23 Test Methods for Notched Bar Impact Testing of Me- tallie Materials El 65/E 165M Practice for Liquid Penetrant Examination for . Grade 6 0.30 0.29-1 .06A 0.025 0.025 min 0.40 max 0.30 max 0.12 Grade 7 0.19 0.90 max 0.025 0.025

Vendor says that they can impact test the material at -49C and demonstrate the absorbed energy same as mentioned in Table 4 of SA 333 material specification.They are reluctant to apply other grades (which are impact tested for lower temperature, and should ideally have been used.)due to cost and sourcing issues.

8" 29mm SA 333 GR 6 Material: A333 Steel 10" Sch 160 Pipe: ASTM A333 Gr6 Thick Wall Seamless Pipe: A333 Carbon Steel Hot Dip Galvanized Pipe: ASME B36.10 SA333 Gr 6 Bevelled SMLS Pipe: SA 333 GR 6 Boiler Pipe: ASTM A333 12" 37mm WT Pipe: ASTM A333 GR 6 Beveled End PCRMO ipe: A333GR6 Sch. 80 200 DN 36 Pipe: Cold Drawn ASTM A333 Grade . According to ASME B31.3 – 2018: Process Piping, the minimum design metal temperature (MDMT) for which ASTM A333 Gr.6 is normally suitable without impact testing other than that required by the material specification is -45°C [-50°F]. However, the boiling point of propylene is -47.7°C, which is beyond the lower limit. According to para. 323.2.2 (h) of the .Get ASME SA 333 GR 6 Seamless Pipe, ASTM A333 Grade 6 Welded Pipe at best price, Check stock Carbon Steel A333 ERW Pipe by sizes. Government recognize export houses; . The lowest temperature for strike test ℉ ℃ SA 333 GR 1-50-45: SA 333 GR 3-150-100: SA 333 GR 4-150-100: SA 333 GR 6-50-45: SA 333 GR 7-100-75: SA 333 GR 8-320-195: SA 333 .

For example, the ASTM A333 Grade 1 pipe has a minimum impact test temperature of -50°C, which has good weldability and high toughness, and is commonly used in applications such as mild low-temperature pipes and equipment. The minimum impact test temperature for ASTM A333 Grade 3 tubing is -150°C. Suitable for extreme low temperature .ASME SA 333 Grade 6 Carbon Steel Seamless Pipes are ASME specification Pipes used for low temperature service.SA 333 Pipes are charpy notch impact tested pipes. Delivering High Quality Pipes & Tubes in API 5L, ASTM A335, A691, A213, A358, A312, A671, SA179, SA192, SA210, A333, SA334, B463, B444 etc.

Note that A333 Gr 6 allows seamless and long-seam pipe manufacturing techniques. That being said, for pipes with long seams, impact toughness of the base metal, weld metal and weld heat-affected zone must be proven and documented. . and is identified as SA333. Note that there may be minor exceptions in the SA version of ASTM standards, and .When the hydrotesting option is chosen instead of NDT, the test pressure will be at 60% of the burst pressure of the pipe. Basic Product Properties: A333 Grade 6: 35 ksi (240 MPa) min. YS 60 ksi (415 MPa) min. UTS Impact Tested to meet Minimum 18J (13 ft-lb) at-45°C (-50°F)

equinox hydromette compact moisture meter

es3000 moisture meter

WEBSportnet forum Dobrodošli na najbolji hrvatski sportski forum! Pravila korištenja. Briljantna predstava oslabljenog Zagreba u Norveškoj, Kolstad opet razbijen . Rukomet. Mandić: 'Pokazali smo da zaslužujemo biti u osmini finala' Rukomet. Hrvatske rukometašice čeka dvomeč s Rumunjskom: 'Mislim da je super što nemamo uopće vremena' .

sa 333 gr 6 impact test|a333 gr6 minimum temp